Managing medical devices in Kenya demands strict compliance with the standards set by the Pharmacy and Poisons Board (PPB). These rules protect the public, promote product quality, and ensure that only safe devices reach the market.

In recent years, PPB has strengthened regulatory oversight to align Kenya with global best practices.

As a result, manufacturers, distributors, healthcare facilities, and importers must understand and follow these guidelines carefully.

Understanding PPB’s Role in Medical Device Regulation

The Pharmacy and Poisons Board serves as the national regulatory authority for medical devices in Kenya. PPB oversees all activities related to registration, importation, distribution, installation, usage, and post-market surveillance of medical devices.

PPB’s mandate ensures that every device placed on the Kenyan market meets approved standards for safety, performance, and quality. This protects patients from device failures and promotes trust in the healthcare system.

What Counts as a Medical Device in Kenya?

PPB defines a medical device as any instrument, apparatus, implant, machine, software, or material intended for medical purposes such as:

-

Diagnosis

-

Prevention

-

Monitoring

-

Treatment

-

Support or modification of bodily functions

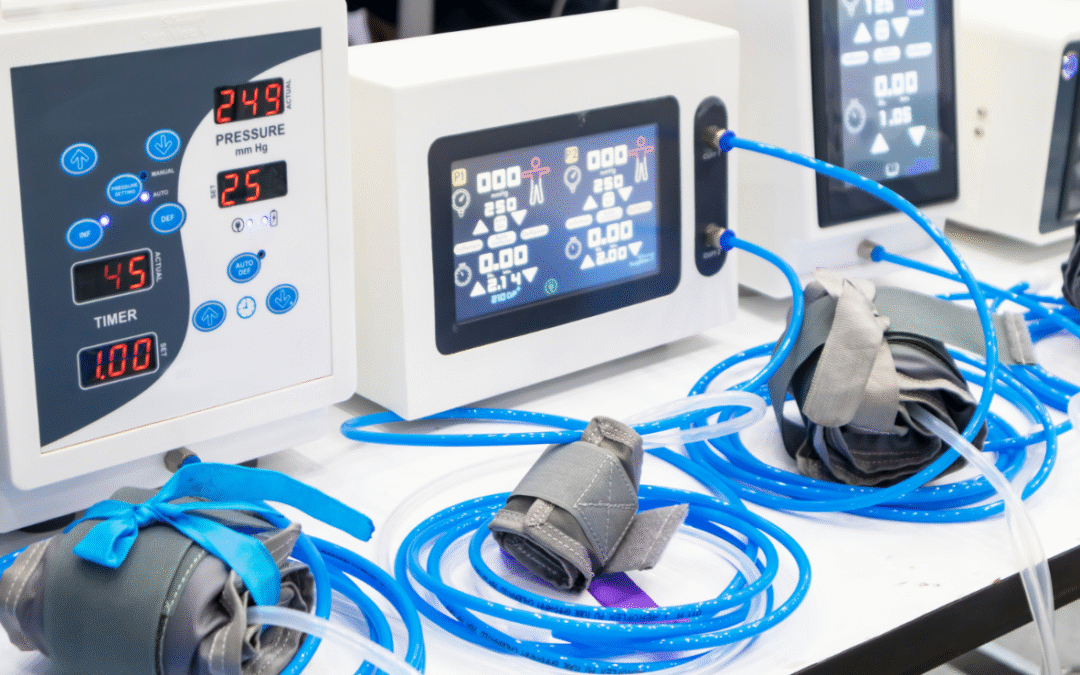

This definition includes items like syringes, blood pressure monitors, infusion pumps, surgical equipment, laboratory analyzers, and medical software.

Medical Device Classification under PPB

PPB classifies medical devices into four main categories based on risk level. Understanding this classification is essential because it determines:

-

Required documentation

-

Approval timelines

-

Registration fees

-

Post-market obligations

Class A – Low Risk

Examples: tongue depressors, surgical gloves, walking sticks.

Class B – Low to Moderate Risk

Examples: suction pumps, infusion sets.

Class C – Moderate to High Risk

Examples: ventilators, infusion pumps, neonatal incubators.

Class D – High Risk

Examples: defibrillators, heart valves, implantable pacemakers.

This classification aligns with the International Medical Device Regulators Forum (IMDRF) framework.

Registration Requirements for Medical Devices

PPB requires registration of all medical devices before placement on the Kenyan market. The process verifies product safety, quality, and compliance with technical standards.

Key Registration Requirements

-

Manufacturer authorization

-

Free Sale Certificate from country of origin

-

Quality management system documentation (e.g., ISO 13485)

-

Device description and intended use

-

Clinical evaluation or performance data

-

Risk classification

-

Labeling and packaging information

The PPB registration process is managed through the UDES (Unified Drug and Device Electronic System) platform.

Importation & Distribution Requirements

PPB regulates the importation and distribution of all medical devices. No individual or company may import devices without proper licensing.

Importation Requirements

-

Valid device registration

-

Import license for medical devices

-

Customs documentation

-

Batch traceability records

PPB also verifies that distributors maintain quality systems that ensure proper storage, transportation, and handling of medical devices.

Installation and Usage Standards

Some devices require installation and calibration before use. PPB emphasizes proper installation by qualified personnel, especially for high-risk devices such as imaging equipment.

Facilities must ensure that:

-

Installers are certified

-

User training is documented

-

Maintenance logs are kept

-

Equipment is calibrated regularly

These measures reduce operational risks and enhance patient safety.

Post-Market Surveillance (PMS)

Post-market surveillance is a key component of PPB regulation. PPB continuously monitors medical devices already in use to detect:

-

Quality issues

-

Adverse events

-

Device failures

-

Counterfeit products

Healthcare facilities must report adverse events or device malfunctions promptly. This requirement helps PPB take action, including product recalls and safety notices.

Quality Control and Compliance

To maintain compliance, facilities and distributors must establish strong internal quality systems. These systems ensure proper handling, documentation, and monitoring of all medical devices.

Critical Compliance Practices

-

Maintain updated device records

-

Keep calibration certificates

-

Report any safety concerns

-

Follow storage requirements

-

Train staff on device usage

-

Renew import licenses and registrations promptly

Continuous compliance protects both patients and healthcare providers.

Common Non-Compliance Issues and How to Avoid Them

PPB regularly identifies gaps during inspections. Understanding these common issues helps organizations avoid penalties.

Frequent Non-Compliance Areas

-

Importing unregistered devices

-

Missing calibration records

-

Poor device storage

-

Incomplete documentation

-

Failure to report adverse events

Organizations can avoid these mistakes by conducting internal audits and ensuring all documentation is up to date.

Why Compliance Matters

Compliance protects patient safety and enhances operational efficiency. It also strengthens business credibility and prevents legal penalties such as:

-

Suspension of import licenses

-

Product seizures

-

Financial penalties

-

Facility closure

Following PPB guidelines ensures that healthcare providers deliver safe and reliable medical services.

How Clarity Pharma Consultancy Can Help

If you work with medical devices, navigating PPB regulations can feel overwhelming. Clarity Pharma Consultancysupports healthcare facilities, importers, and distributors by offering:

-

Guidance on device registration

-

Compliance audits

-

Documentation support

-

Importation and licensing assistance

-

PMS reporting support

-

Quality management advisory

Their expertise ensures your organization remains compliant and avoids regulatory challenges.

For consultation or regulatory assistance, consider partnering with Clarity Pharma Consultancy.

Managing medical devices under PPB regulations requires attention to detail, proper documentation, and ongoing compliance.

By understanding device classification, registration requirements, importation controls, and post-market obligations, organizations can operate safely and confidently. Staying compliant not only protects patients but also strengthens the entire healthcare system.

FAQs

Do imported medical devices need registration?

Every imported medical device must be registered with PPB before entering the Kenyan market.

What is the role of post-market surveillance?

PMS monitors device performance, detects safety issues, and supports product recalls when necessary.

Can a distributor sell devices without a PPB license?

No. Distributors and importers must hold valid licenses issued by PPB.