Ensuring the quality of medicines is essential for protecting public health. In Kenya, the Pharmacy and Poisons Board (PPB) serves as the national regulatory authority responsible for safeguarding the quality, safety, and efficacy of all medical products circulating in the country.

One of the Board’s most important functions is batch release testing, a quality assurance procedure that verifies whether every batch of a medicine meets the required standards before entering the market.

This article explains how batch release testing works, why it matters, and how PPB strengthens Kenya’s pharmaceutical safety landscape.

Understanding Medicines Quality Assurance in Kenya

Medicines quality assurance refers to the systems and processes used to ensure that medicines consistently meet the standards required for safe use. PPB oversees this responsibility as mandated under the Pharmacy and Poisons Act, Cap 244.

Quality assurance covers many aspects of the product lifecycle, including:

-

Manufacturing quality

-

Storage and distribution

-

Laboratory testing

-

Post-market surveillance

Batch release testing is a key component of this framework.

What Is Batch Release Testing?

Batch release testing is the process where regulatory authorities evaluate laboratory test results from each batch of a medicine before approving it for distribution. This verification ensures that the product meets all specified quality requirements, such as potency, purity, and stability.

Manufacturers submit:

-

Certificates of analysis

-

Quality control results

-

Compliance evidence

-

Product specifications

PPB assesses these documents and may conduct independent laboratory testing to confirm the results.

Why Batch Release Testing Matters

Batch release testing protects the public from unsafe or substandard medicines. It also strengthens trust in the healthcare system by ensuring that medicines available in pharmacies, hospitals, and clinics are safe and effective.

It helps prevent:

-

Contaminated products

-

Counterfeit medicines

-

Improper formulations

-

Production errors

-

Distribution of failed batches

Through this process, PPB reduces the risk of adverse events and ensures compliance with national and international quality standards.

PPB’s Mandate in Medicines Quality Control

PPB evaluates every batch of certain high-risk medical products, including vaccines, biologicals, and sterile preparations. Its authority draws from national laws and global best practices recommended by the World Health Organization (WHO).

The Board undertakes several activities during batch release testing:

-

Reviewing documentation for completeness

-

Analyzing laboratory data

-

Conducting physical and chemical verification

-

Confirming packaging and labeling specifications

-

Approving or rejecting the batch for use

These actions ensure that only high-quality products reach the Kenyan market.

How PPB Conducts Batch Release Testing

PPB follows a structured process to guarantee accuracy and fairness.

1. Submission of Batch Documentation

Manufacturers or importers submit a certificate of analysis and supporting data. The information describes the quality attributes of the batch and must comply with established specifications.

2. Verification of Compliance

PPB reviews each document to confirm compliance with regulatory standards. The Board checks for consistency, completeness, and accuracy.

3. Laboratory Testing (When Required)

PPB may send samples to accredited laboratories for further analysis. These tests confirm the results provided by the manufacturer and ensure that no critical issues were overlooked.

4. Evaluation of Test Results

PPB assesses the combined evidence to determine whether the batch meets safety and quality requirements.

5. Issuance of Batch Release Certificate

If the batch complies, PPB issues a release certificate. The batch can then be distributed within Kenya.

If not, PPB rejects it and takes corrective action, which may include recalls or destruction.

Products That Require Mandatory PPB Batch Release

Certain categories of medicines undergo mandatory batch release testing due to their high-risk nature. These include:

-

Vaccines

-

Biological medicines

-

Blood products

-

Antivenoms

-

Sterile injectables

-

Certain imported pharmaceuticals

These products require strict quality assurance because even minor deviations can cause severe harm.

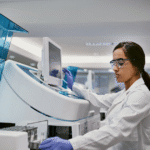

The Role of Laboratories in Batch Release Testing

PPB collaborates with accredited laboratories to verify product quality. These labs use standard analytical techniques such as:

-

High-Performance Liquid Chromatography (HPLC)

-

Microbial purity testing

-

Sterility testing

-

Dissolution profile analysis

This cooperation enhances transparency and ensures scientific integrity during the evaluation process.

Batch Release Testing and Public Health Protection

By enforcing batch release testing, PPB significantly improves public health outcomes. Substandard or falsified medicines can lead to treatment failure, antimicrobial resistance, or life-threatening side effects. Batch release testing minimizes these risks.

The Board also contributes to global security frameworks, aligning Kenya with WHO standards on pharmaceutical regulation.

Common Challenges in the Batch Release Process

Although essential, batch release testing may face challenges such as:

-

Delays in document submission

-

Insufficient laboratory capacity

-

Incomplete quality control data

-

Shortages of testing materials

-

Inconsistent manufacturer compliance

PPB continually strengthens its systems to address these issues through automation, capacity building, and digital transformation.

How Clarity Pharma Consultancy Can Support You

Clarity Pharma Consultancy helps pharmaceutical businesses meet PPB requirements with ease. The consultancy offers guidance on batch release preparation, regulatory submissions, and compliance improvement.

If you need expert support in navigating PPB procedures, Clarity Pharma Consultancy provides reliable and professional assistance to keep your pharmaceutical operations compliant and efficient.

Batch release testing plays a vital role in ensuring medicines circulating in Kenya meet the highest quality standards. PPB continues to safeguard public health by verifying every high-risk batch before distribution.

This process strengthens the healthcare system, protects consumers, and aligns Kenya with global regulatory expectations.

Pharmaceutical businesses must understand and comply with these requirements to ensure their products remain safe, legal, and market-ready.

FAQs

Why does PPB conduct batch release testing?

PPB performs batch release testing to ensure medicines are safe, effective, and compliant with quality standards.

Which products require mandatory batch release?

Vaccines, biologicals, antivenoms, blood products, and sterile injectables typically require batch release approval.

How long does batch release take?

Timelines vary depending on product type, documentation quality, and laboratory testing needs.